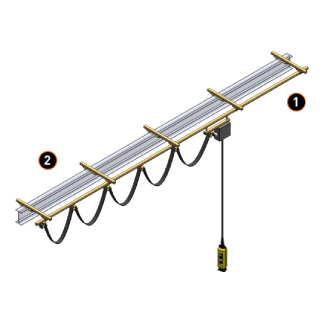

A standard kit comprises of:

- Track (supplied in 3m or 6m lengths)

- Track joints (where necessary)

- Track supports (every 1.5m)

- 1 x End clamp

- Cable trolleys (every 1.5m to give a cable loop depth of 0.75m)

- 1 x Towing trolley

- 1 x End stop

- Cable or hose

- 2 x Glands

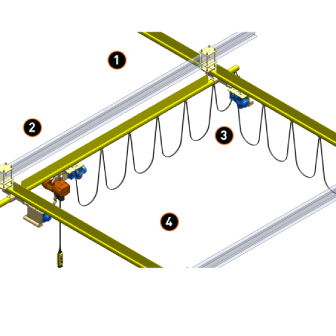

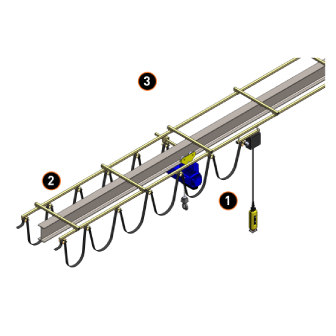

Power and pendant supply systems are used to feed both power and control cables or hoses to overhead cranes and other moving machinery.

A standard kit comprises of:

- 2 runs of track (supplied in 3m or 6m lengths)

- Track joints (where necessary)

- Track supports (every 1.5m)

- 1 x End clamp

- Cable trolleys (every 1.5m to give a cable loop depth of 0.75m)

- 1 x Pendant trolley (supporting a terminal box or plug and socket connection)

- 1 x Towing trolley

- 2 x End stop

- Cable or hose

- Glands