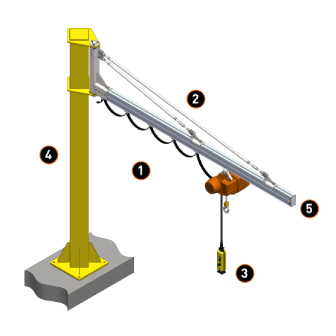

SWL: 25 – 2000kg

Arm length: up to 6m

Column height: up to 6m

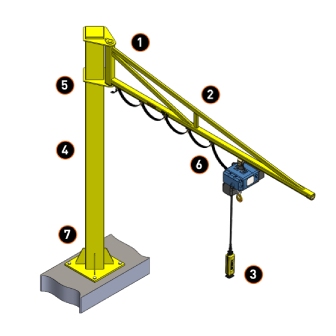

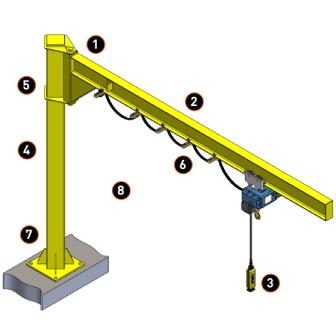

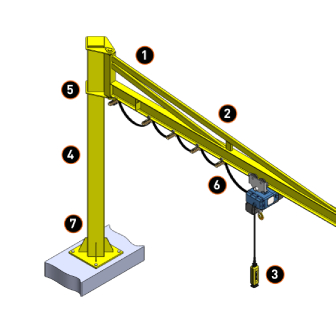

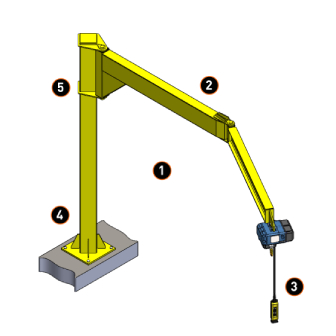

Arm types: profile track, under-braced I-beam, over-braced I-beam and articulated/knuckle

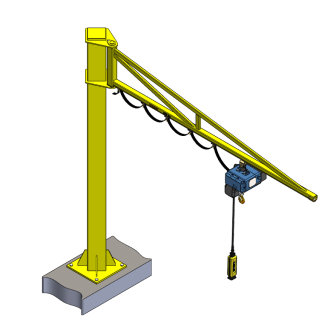

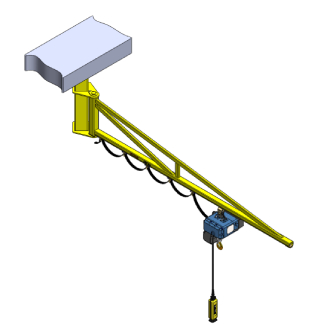

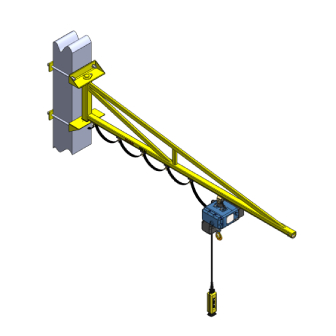

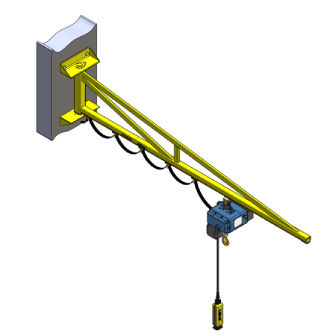

Fixing: freestanding, wall fixing, clamp around/column fixing

Slewing arc: 270° on standard arms or 360° on articulated arms

Finish: powder coated, hot dip galvanised or stainless steel

Designed in accordance with BS 7333 : 1990

Discover the most comprehensive range of jib cranes! Standard or customised, NIKO crane systems has a solution for lightweight lifting.