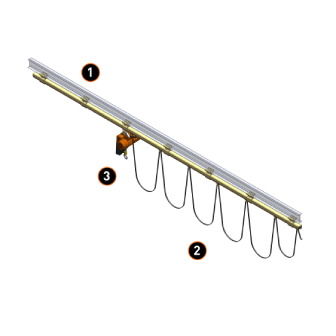

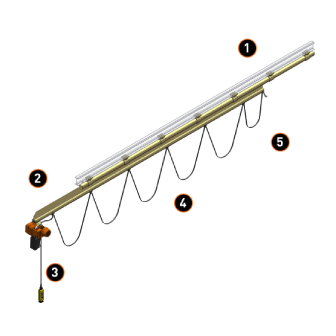

- Steel / Aluminium / Stainless Steel 304 or 316

- Zinc plated / powder coated / hot dip galvanised

- 500km life span

- Nylon wheels for near silent operation

- 1% force to move

- Manual / Powered

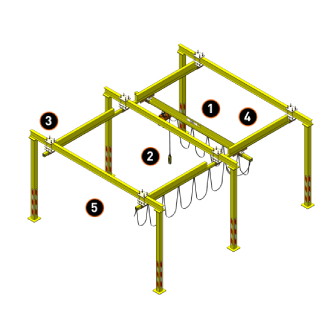

- EN 16851 Light Cranes

- EN 1090 Structures

- EUROCODES

- CE Marked to EC Machine Directive

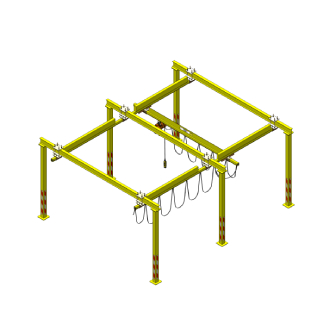

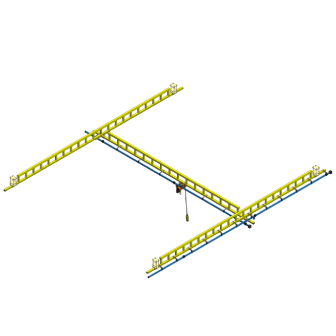

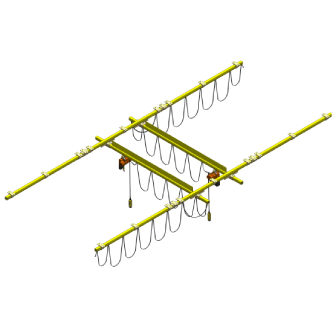

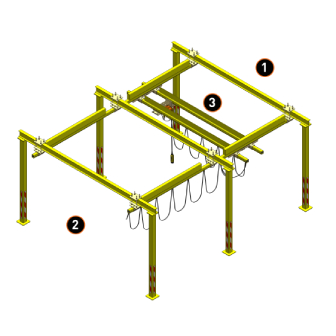

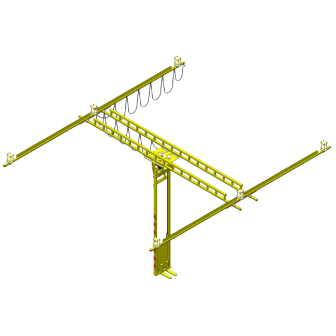

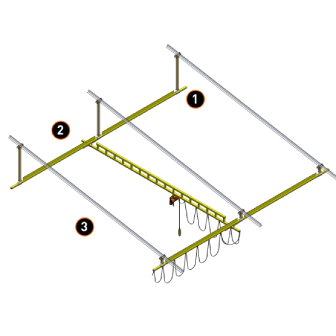

Rigid light crane systems provided by NIKO crane systems are an ergonomic and cost effective solution to conventional overhead crane systems with loads up to 2.000kg and 10m. bridge length. The systems can be applied in various industries related to lifting applications like warehousing and logistics, assembly lines, manufacturing processes and generally for handling loads across a working area. The key advantage is the elimination of manual handling and the reduction of work injuries. From standard systems to customized solutions, we have your lifting needs covered!